What can you expect?

Prusament ASA is our own in-house made filament. The whole manufacturing process is closely monitored and tested - we guarantee ±0.04mm precision and highly-consistent colors. You can inspect the parameters of every spool we made at prusament.com. Check the sample spool!

Manufactured In-House By Josef Prusa

We were not satisfied with the quality of filaments on the market. So we decided to make our own! Prusa Research is the only 3D printer manufacturer with its own filament production.

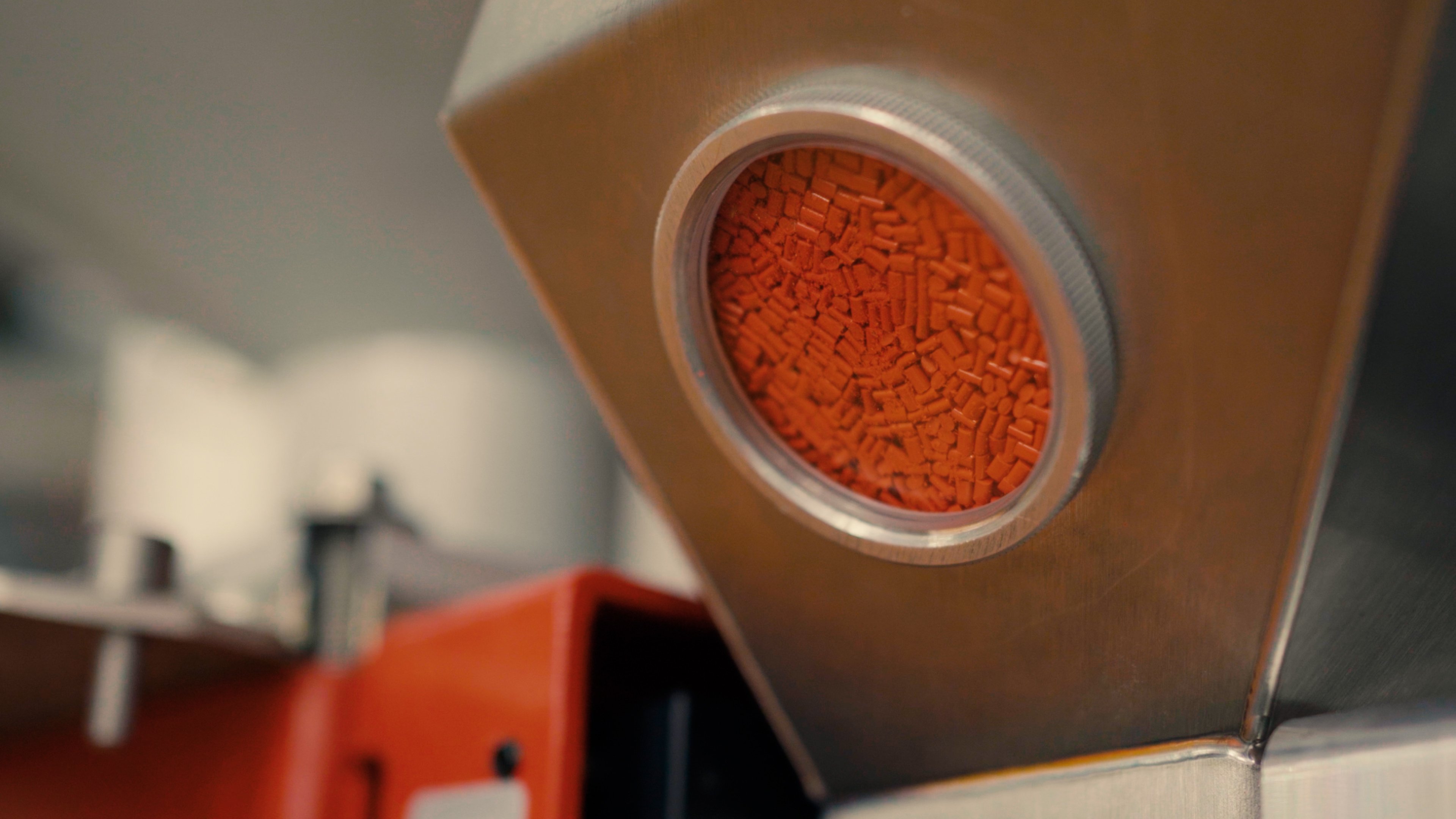

Premium-Grade Materials And Thorough Testing

The whole manufacturing process is closely monitored and tested – string diameter, color consistency, and mechanical properties – to make sure that every spool is perfect.

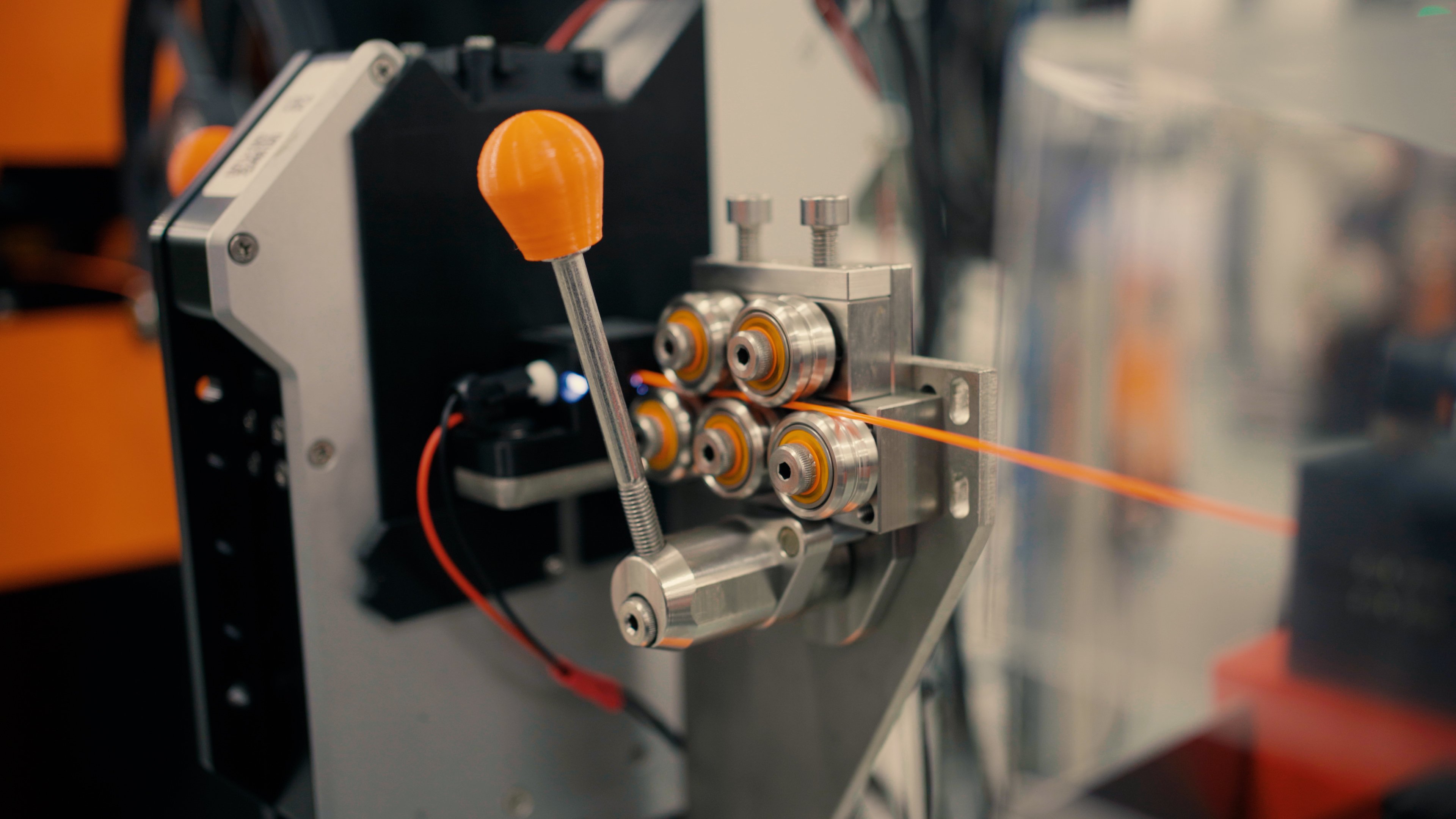

± 0.04 mm Manufacturing Guaranteed Precision

We guarantee ±0.04mm precision and highly-consistent colors in our filaments.

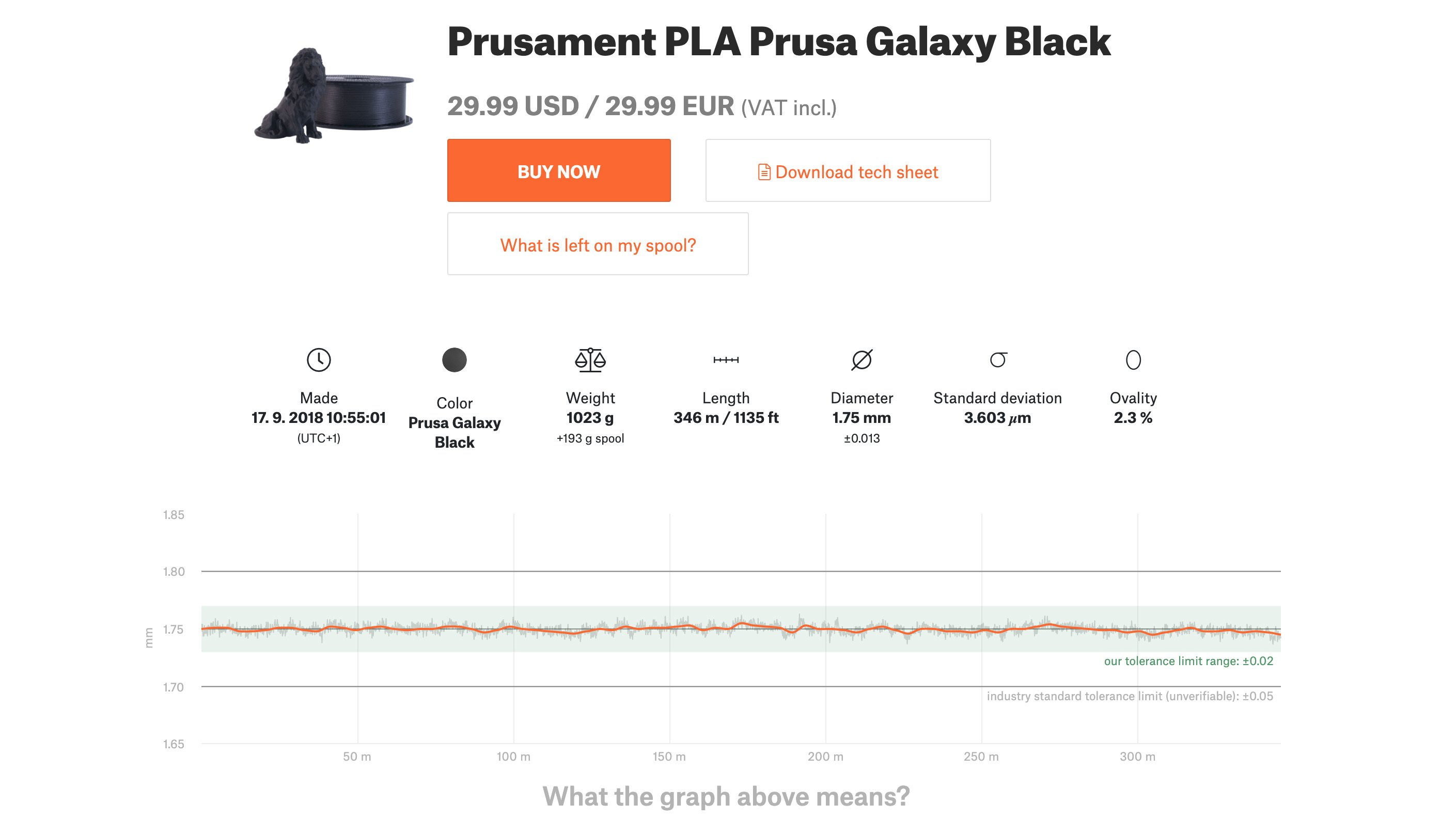

High Quality You Can Check Yourself

We are the only manufacturer that gives the option to inspect parameters of every filament spool. Scan a QR code on the spool to see all details online (check the sample spool).

Read more about Prusament in general in the article at blog.prusa3d.com and about Prusament ASA in this article. Or just visit Prusament.com!

About ASA

ASA is a technical material with properties similar to ABS but better in several ways. Compared to ABS, it’s UV stable, it doesn’t suffer from shrinking so badly and the fumes produced are much less noticeable. ASA 3D prints are durable, tough and suitable for a wide range of applications. ASA comes with much better high-temperature resistance than other common materials, such as PLA or PETG. It shows no signs of deformation up to temperatures near 93 °C. Thanks to all these properties, ASA is especially suitable for printing objects meant for long-time outside use.

Printing Setup

| Nozzle | 260±5 °C |

| Heatbed | 110±5 °C |

| Recommended Steel Sheet | Satin |

Basic Attributes

Beginners tips & tricks

You may encounter some issues related to shrinking (warping) of the material – especially when printing larger models. This effect is much less severe compared to ABS but still, even with the heatbed set to 110°C, the prints can shrink and warp, causing them to detach from the print bed. This issue can be eliminated by printing inside an enclosure (for example our Prusa Enclosure) or by adding a draft shield around the object.

It’s important to run the prints in a well-ventilated room because the material releases fumes and substances that could pose a potential health risk. When ventilating the room, do not create a draft around the print – this will negatively impact the result.

You can find more details about printing with ASA in our in-depth article.

Notes

This ASA is made in-house by Prusa Research.

Starting from May 2024, all Prusament ASA spools have a tolerance of +- 0.04 mm instead of 0.03 due to changes to the manufacturing process.

Before printing, make sure the surface of heatbed is clean as described in 3D Printing Handbook.

To dry the filament, please follow the instructions in our article.Preparation time: 1-3 business days.

United States

United States