What can you expect?

Prusament rPLA Natural Pigments is our in-house made PLA filament with ±0.03mm manufacturing tolerance and natural pigments. The filament is made of recycled PLA from industrial waste. No artificial pigments are added; the coloring of this Prusament comes from processed organic waste, resulting in a unique shade for every batch. You can inspect the parameters of every spool we made at prusament.com. Check the sample spool!

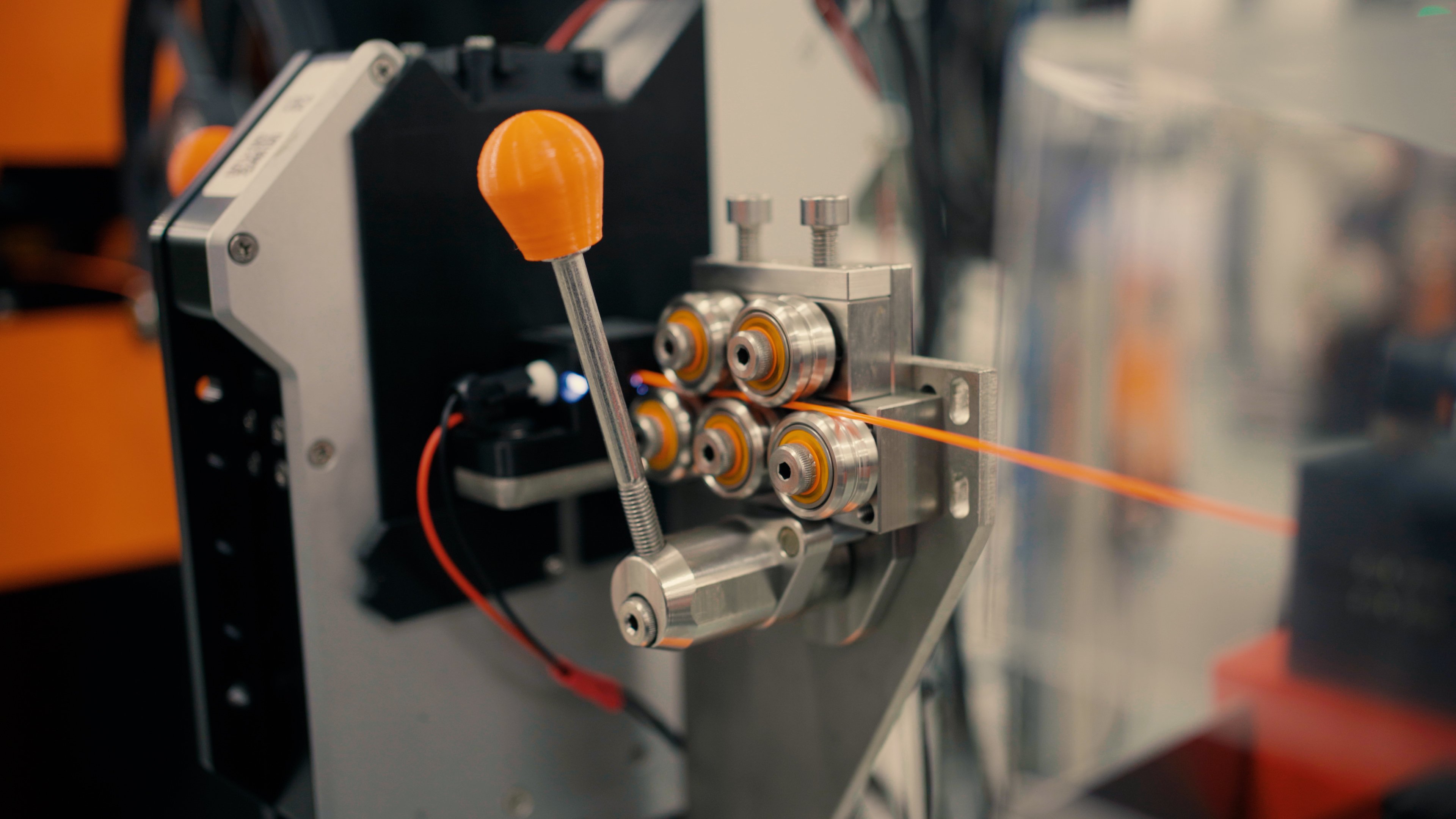

Manufactured In-House By Josef Prusa

We were not satisfied with the quality of filaments on the market. So we decided to make our own! Prusa Research is the only 3D printer manufacturer with its own filament production.

Smart spool design to save material

We are constantly improving our filament spools. The latest iteration features a core from recycled cardboard and lightweight sides from recycled polycarbonate.

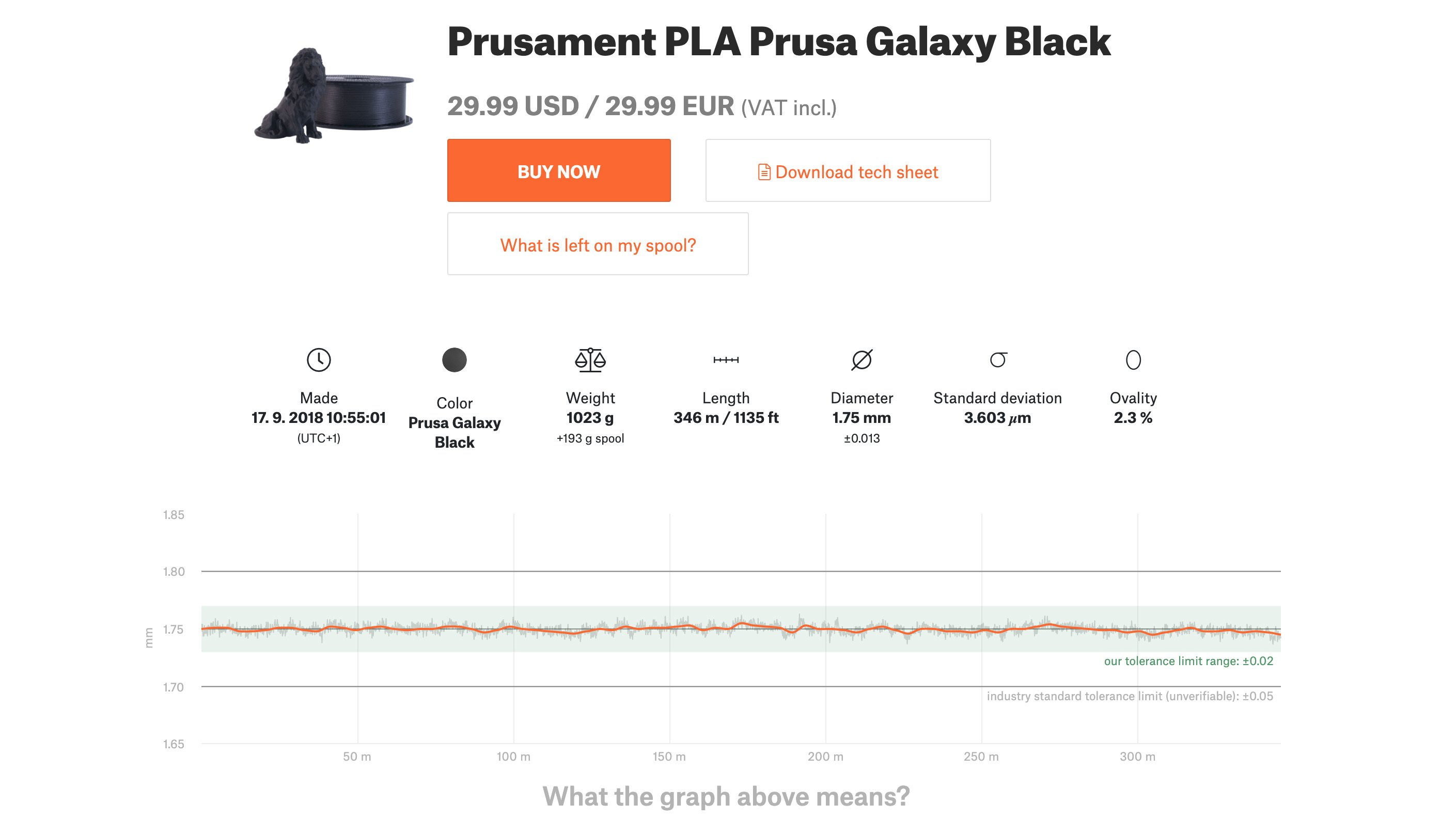

± 0.03 mm Manufacturing Guaranteed Precision

We believe the industry standard of 0.05 mm isn’t sufficient for perfect 3D printing. Instead, we guarantee ±0.03mm precision.

High Quality You Can Check Yourself

With every spool, you have the unique option to inspect its manufacturing parameters yourself. Scan a QR code on the spool to see all details online (check the sample spool).

For our recycled filaments, we had our carbon footprint calculated. You can find more about our sustainability activities in our sustainability report.

Read more about Prusament in the article at blog.prusa3d.com or Prusament.com!

About rPLA

Prusament rPLA Natural Pigments is our own in-house recycled PLA filament with natural pigment additives. The filament is made of PLA parts manufacturing waste provided by our external supplier. No artificial pigment is added, the coloring of this Prusament comes from processed organic waste, such as red algae. The organic additives create a noticeable scent during printing.

The Prusament rPLA Natural Pigments has mechanical properties similar to regular PLA, but it is slightly more brittle and hygroscopic. In general, PLA is used for various aesthetic models, prototypes, and other visual parts. With Prusament rPLA Natural Pigments, these parts can be made with significantly lower ecological impact. Last but not least, the natural pigments give rPLA pleasant subtle colors, perfectly suitable for various home decor and other aesthetic purposes.

Printing Setup

| Nozzle | 205 ± 10 °C |

| Heatbed | 50 ± 10 °C |

| Recommended Steel Sheet | Smooth PEI / Textured / Satin |

Basic Attributes

Beginners tips & tricks

Popular among both beginners and advanced users

PLA is the easiest-to-print filament we make. It’s reliable and it doesn’t require any print preparations or difficult post-processing methods. If you’re new to 3D printing, it’s best to start with PLA before using other materials.

Sanding

When post-processing PLA, it’s better to use wet sanding. Without water you’ll quickly start heating the plastic by friction, it will melt locally and deform. Also, without water, the sanding material would clog easily.

Gluing

PLA can be glued with many types of glue. We recommend using superglue for most of the parts. Certain PLA filaments may be also glued using acetone, however, it strongly depends on the various additives and colors used.

For our recycled filaments, we had its carbon footprint calculated. You can find more about our sustainability activities in our sustainability report.

Notes

This rPLA is made in-house by Prusa Research.

1.75 mm filament is manufactured with precision of +- 0.03 mm

Before printing, make sure the surface of heatbed is clean as described in 3D Printing Handbook.To dry the filament, please follow the instructions in our article.

United States

United States