What can you expect?

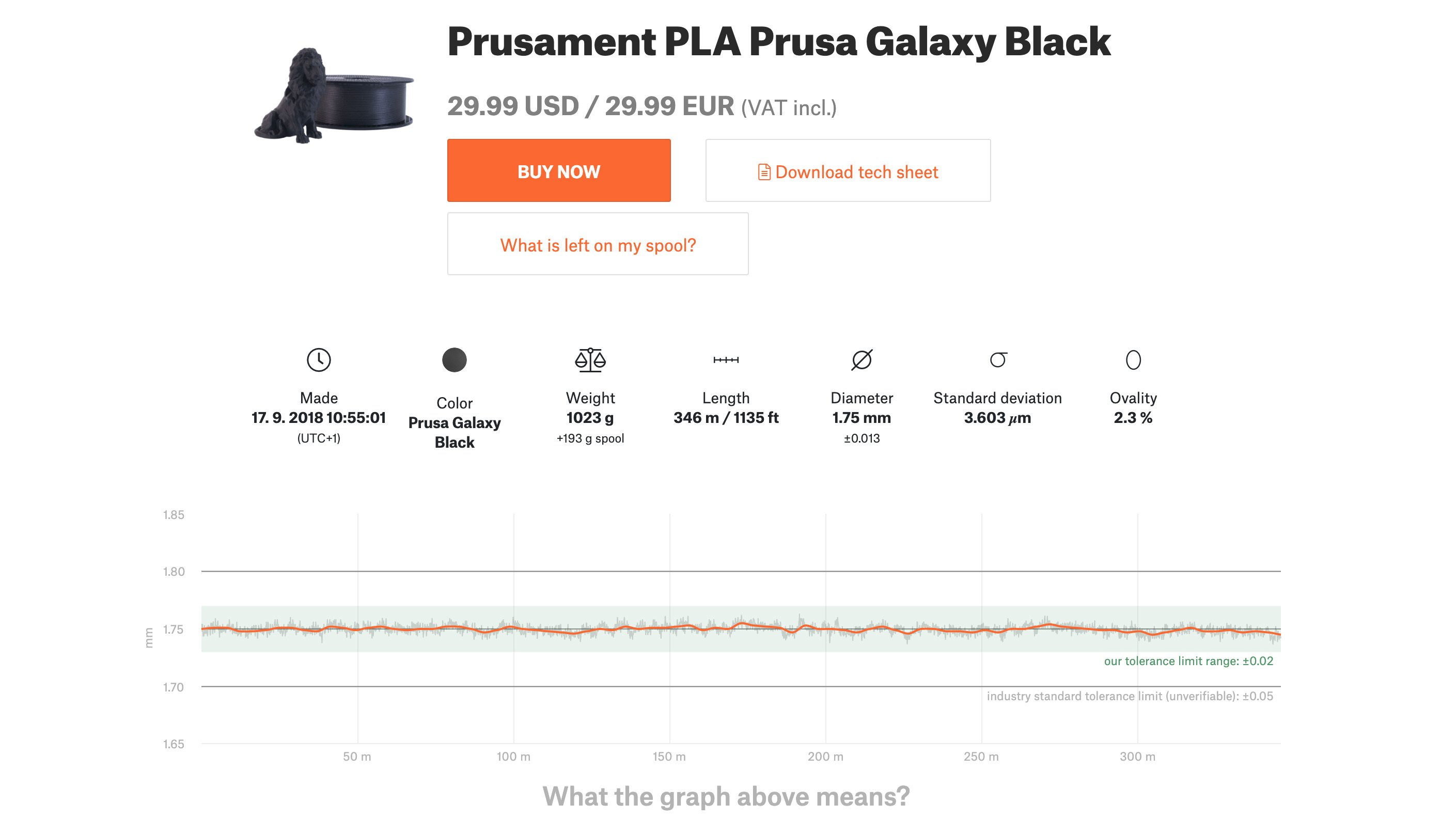

Prusament PETG Recycled is our own in-house made filament with ±0.05mm manufacturing tolerance. 100 % of the material consists of recycled Prusament PETG materials, so every batch has a different color. You can inspect the parameters of every spool we made at prusament.com. Check the sample spool!

Made only from recycled Prusament PETG

Waste produced during our in-house production of Prusament PETG is recycled and used as a base for Prusament PETG Recycled. There are no further additives or pigments in the mix.

Smart spool design to save material

We are constantly improving our filament spools. The latest iteration features a core from recycled cardboard and lightweight sides from recycled polycarbonate.

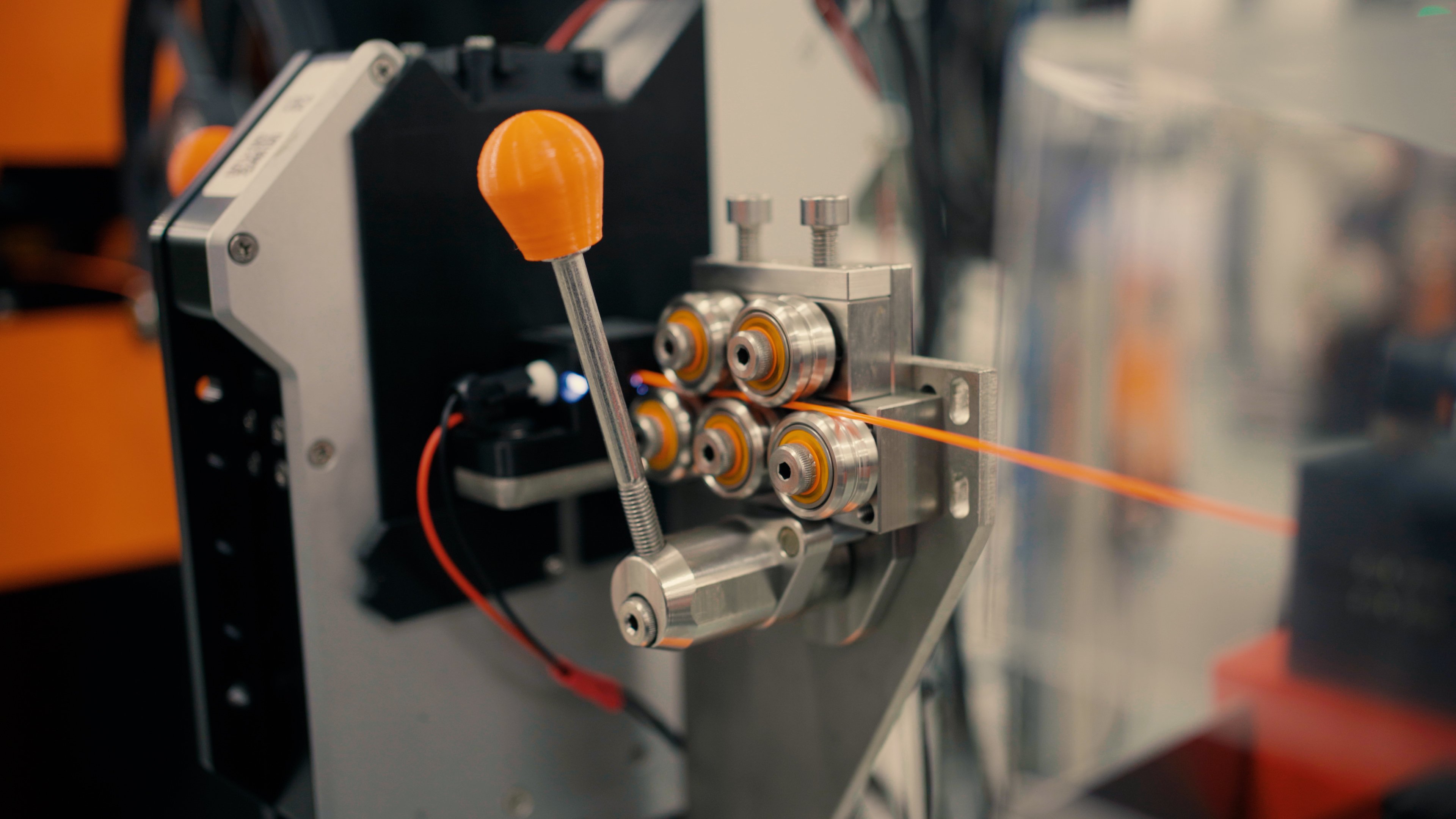

Guaranteed ± 0.05 mm Manufacturing Precision

Even our recycled PETG material is subjected to strict QA control, so you can be sure that your prints will go smoothly and without a hitch.

High Quality You Can Check Yourself

With every spool, you have the unique option to inspect its manufacturing parameters yourself. Scan a QR code on the spool to see all details online (check the sample spool).

For our recycled filaments, we had our carbon footprint calculated. You can find more about our sustainability activities in our sustainability report.

Read more about Prusament in the article at blog.prusa3d.com or Prusament.com!

About PETG Recycled

Prusament PETG Recycled is our own in-house filament. 100% of the material consists of shredded Prusament PETG filaments that didn’t pass our strict control, so every batch has a different color. Due to its excellent layer-to-layer adhesion, PETG prints are ideal for indoor and outdoor waterproof applications. Furthermore, PETG is a tough material with good high-temperature resistance. The G in the acronym stands for a glycol-modified substance that is present during the manufacturing process. It modifies the properties of PET, so that it’s easier to print, less brittle, and clearer when printing with semi-transparent variants. PETG has a low thermal expansion, so even when printing big objects, and without an enclosure, it rarely lifts from the bed and warps. In addition to that, PETG has a healthy amount of flex which can prevent parts from breaking under pressure. We use PETG to print parts for our printers!

Printing Setup

| Nozzle | 250 °C |

| Heatbed | 70-90 °C |

| Recommended Steel Sheet | Textured / Satin |

Basic Attributes

Low shrinking and warping

Possibility of stringing

Poor bridging characteristics

Beginners tips & tricks

Unlike PLA or ABS, PETG tends to ooze a bit and may leave strings of plastic on your print. We suggest drying the filament before printing, as described here. If stringing still occurs, you may further counter it by increasing retraction and playing with hotend temperature, but if you use our filament presets in Prusa Slicer, we already did that for you and the amount of stringing should be minimal. Or, you can get rid of the strings by briefly blasting your finished prints with a heat gun.

Notes

This rPETG is made in-house by Prusa Research.

1.75 mm filament is manufactured with precision of +- 0.05 mm

Before printing, make sure the surface of heatbed is clean as described in 3D Printing Handbook.

The 2kg spool won't fit the standard spoolholder, please download and print the 2kg spoolholder.

To dry the filament, please follow the instructions in our article.

- PETG Recycled Universal Can Press Remix by Michal Fanta

- Mini watering can by Martin

- Lawn Weed Puller by A_Str8

- Gardening tools 2021 by MrHanjak

- Rectangular storage box by chuotdong

- Pet Bottle Spout by wdvc

- Planter with self-watering by Laurens.v

- Self-watering connectable flowerpot by Martin

- Model Painting Handle by fetchbeer

Filament color

Preparation time: 1-3 business days.

United States

United States