United States

United States🔥 Reduced FedEx Shipping for CORE One! 🚀

About us

Hello, we are Prusa Research!

And we make more than just amazing 3D printers!

Prusa Research was founded as a one-man startup in 2012 by Josef Prusa, a Czech hobbyist, maker and inventor - and now one of the most famous names in the 3D printing industry.

Josef found his passion for 3D printers as a student of University of Economics in Prague. That was in 2009. Back then, he considered 3D printing to be nothing but a hobby, an amazing new technology open to changes and improvements. Josef then joined the open-source RepRap project and the rest is history.

It's pretty cool history, actually! Scroll down and see how Prusa Research was born and how we reached the top of the global charts!

We started really small. There were no investors, no Kickstarter campaigns. Just a man with a plan (and a huge stack of pizza boxes, which were used to ship 3D printer parts from a small basement workshop to the whole world). The beginnings were modest, but pretty exciting!

As time went by, the Prusa i3 design became one of the most popular FDM 3D printer designs adopted by many manufacturers and hobbyists across the world thanks to its open-source nature.

And now? Now, there are more than 900+ people working in Prusa Research and we ship over 10 000 printers worldwide directly from our HQ in Prague every month! We have become the no.1 fastest growing tech company in Central Europe (Deloitte 2018) with a growth rate of 17118 % over the last four years and claimed the no.1 spot in Deloitte's 2019 BIG 5 category with the growth rate of 4527 %!

But despite all these numbers, visiting Prusa Research is like visiting a craftsman's workshop - a workshop sprawling across eight floors of a huge old Prague factory! We develop our own hardware and software, invent, improve, tinker, experiment and do all sorts of awesome stuff.

And we are staying faithful to our roots. Our award-winning Original Prusa i3 3D printers are still open-source and plenty of their parts are printed by other 3D printers - that’s why we also have “The Farm”, a large hall with more than 600 printers that create parts for other printers!

How We Make Our 3D Printers

We would like to take you on a tour of our factory in the heart of Europe, and show you how a 3D printer comes to life! We'll show you the entire journey starting from a 3D-printed plastic part all the way to packing and shipping. And so much more!

Five years ago, we published the Road to 100.000 3D printers video showing our history and how we do stuff at Prusa Research. And since then, we didn't stop for a moment. New printers, new manufacturing methods, new technologies - but above all: new people! We're now more than twice as big as we were back then! So, sit back, relax and let us take you to an awesome place in Prague, Czech Republic!

Open-source and why it matters

Prusa Research grew from Josef Prusa’s work in the RepRap project. Our mission is clear: make enjoyable machines for everyone to use. Open-source is our heart, we strongly believe in the community and in sharing how we do things so others can learn and create.

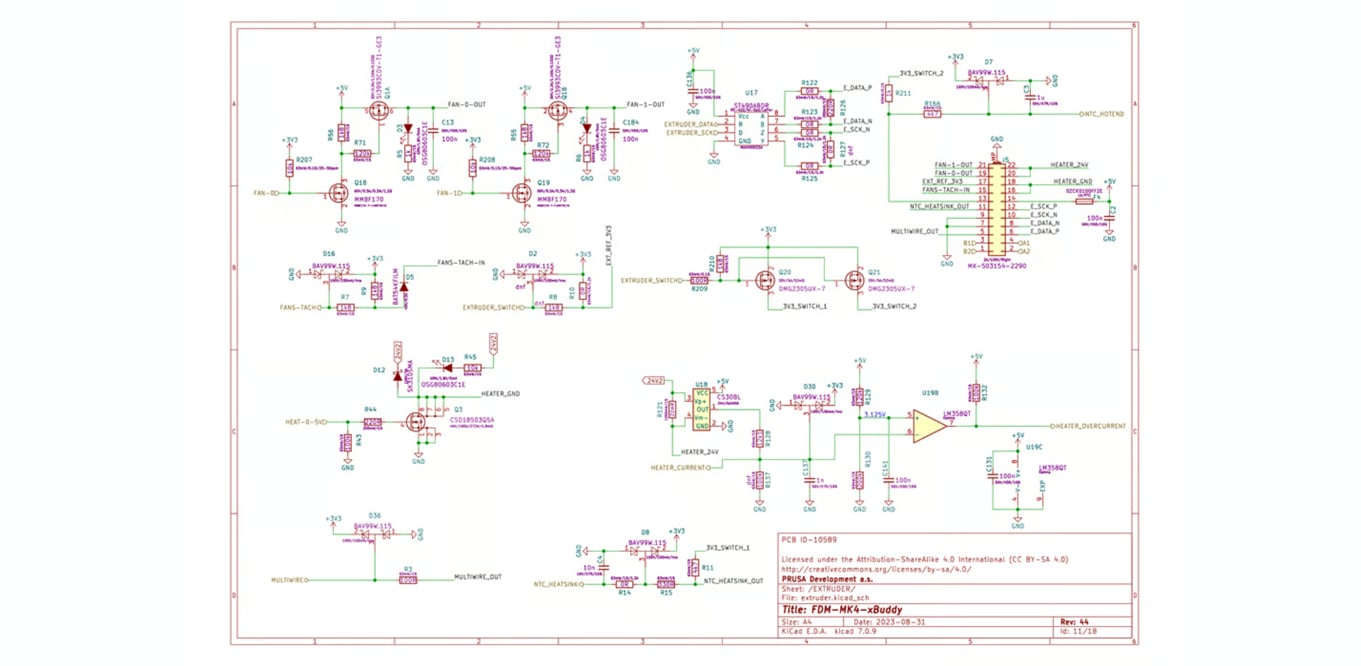

Our goal is for our printers to remain moddable, easily repairable, and produce amazing prints even decades after their initial release. Reprint the plastic parts, flash custom firmware, read through our circuit board designs, or completely modify our printers to meet your specific needs.

Products and Projects

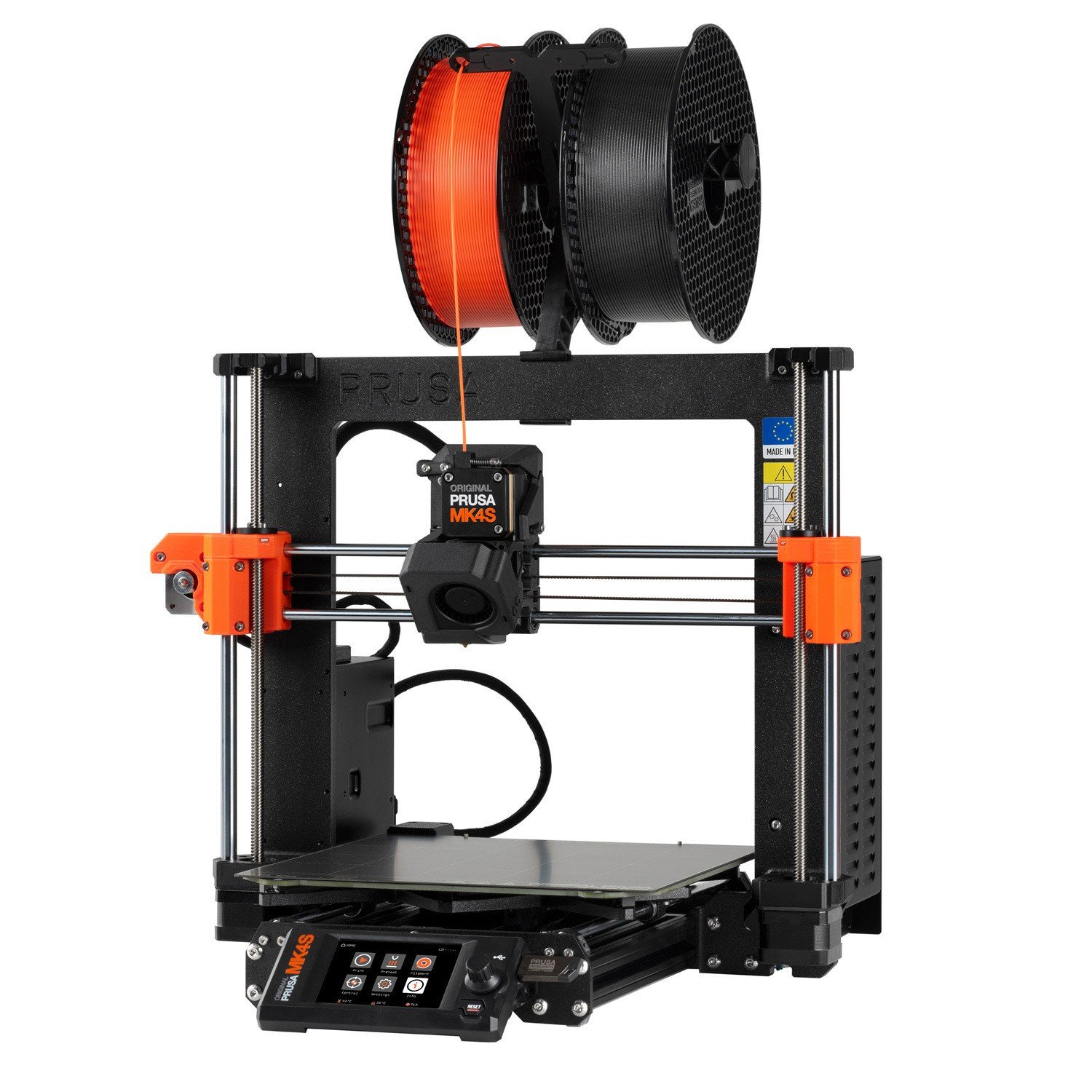

Original Prusa MK4S

Reliable and easy to use high-speed 3D printer

Original Prusa MK4S is the successor to our award-winning Original Prusa i3 MK3S+. It has all the best features of the popular MK3 – an open-source 3D printing workhorse with easy maintenance and advanced safety features – and adds much more!

The MK4 will consistently deliver a perfect smooth first layer thanks to the Loadcell sensor (no manual adjustments needed). The next-gen extruder (Nextruder) and 32-bit connected platform provide many quality-of-life improvements like remote printing, quick-swap nozzles, and customizable UI with a one-click printing option. It also supports high-speed printing with Input Shaper and Pressure Advance. And it’s still beautifully quiet. Thanks to the 360° cooling, the MK4S allows you to print overhangs of up to 75° without supports, significantly cutting down on print costs and time. Network features include Prusa Connect, which allows to remotely control your printer from anywhere in the world!

The functionality of the MK4S can be further expanded with our unique MMU3 addon for printing with up to 5 materials simultaneously.

The MK4S is available both assembled and as an assembly kit.

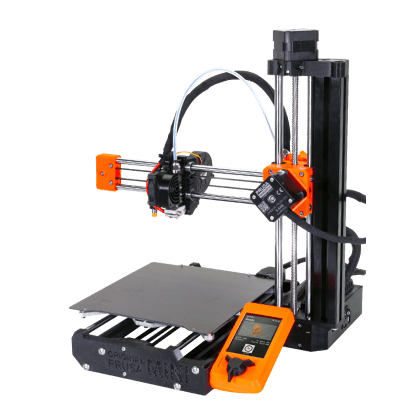

Original Prusa MINI+

Smart and compact 3D printer for everyone

The Original Prusa MINI+ is our new compact 3D printer with all the bells and whistles you would expect from the creators of the award-winning Original Prusa i3 MK2 and MK3S+!

The MINI+ is a big printer in a compact body. We did our best to squeeze as many features into the lowest possible price as possible.

The MINI+ is great for beginners, companies looking to build a printing farm and 3D printing enthusiasts worldwide.

Original Prusa XL

Large-scale CoreXY 3D printer

The Original Prusa XL is a large-scale CoreXY 3D printer with a build volume of 36×36×36 cm (14.17’’×14.17’’×14.17’’). Featuring an optional tool changer with up to 5 independent tool heads, automatic first layer calibration for an always-perfect first layer, and many smart features.

The XL comes with the brand new “Nextruder”, a completely redesigned extruder with a planetary gearbox, hot-swappable nozzles and a Load Cell-based system for fully automatic first layer calibration. The print quality is further enhanced by the XL’s modular bed design - instead of using a single large heatbed, which is prone to warping, the XL uses an array of smaller, individually-controlled segments. Only the necessary part of the heatbed is activated when printing smaller objects, making the XL energy-efficient. The XL can be easily expanded up to five tool heads thanks to a highly accurate tool changer with automatic calibration via the load cell sensor. Our internally developed kinematic coupler mechanism ensures millions of trouble-free tool changes. The tool heads are available individually in our e-shop as optional upgrades.

Original Prusa SL1S SPEED

Fastest MSLA 3D Printer

The Original Prusa SL1 was our first foray into the world of SLA printers. We wanted to build a solid, sturdy and robust 3D printer that would produce consistent, high-quality 3D prints. Based on the general feedback and reviews, we did many things right. The SL1 found its way not just into hobbyists’ workshops but into various industries as well.

The vastly improved version of the SL1 is finally here! Called SL1S SPEED, it features a brand new high-resolution monochrome LCD and high-performance optics, a larger print platform, and all cumulative updates from the entire lifespan of the SL1. The new SL1S SPEED is a lightning-fast machine that requires just 1.6 seconds per single to produce amazingly detailed 3D prints.

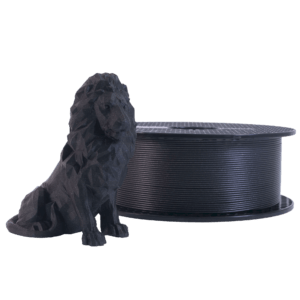

Prusament

Premium-quality materials for 3D printing

Prusament is our line of in-house made filaments and resins. The advanced manufacturing process allows for a higher level of quality control, more efficient testing and guaranteed manufacturing precision.

Each spool of our filament has perfect winding and is meticulously tested. The complete manufacturing reports are available online, enabling customers to see detailed properties of every spool they have purchased. Prusa Research is the only company providing its customers with this unique option.

The range of materials under the Prusament brand was expanded with high-quality in-house-made resins in 2021.

Prusa Pro AFS

Autonomous Farm System

Introduced as a fully-functional prototype at EXPO 2020 in Dubai, the Prusa Pro AFS is the next-generation solution for rapid prototyping and small-batch production. Featuring 34 new Original Prusa CoreXY 3D printers, automatic collecting mechanisms, and a simple-to-use touchscreen interface, the AFS is the perfect solution for both large and small businesses.

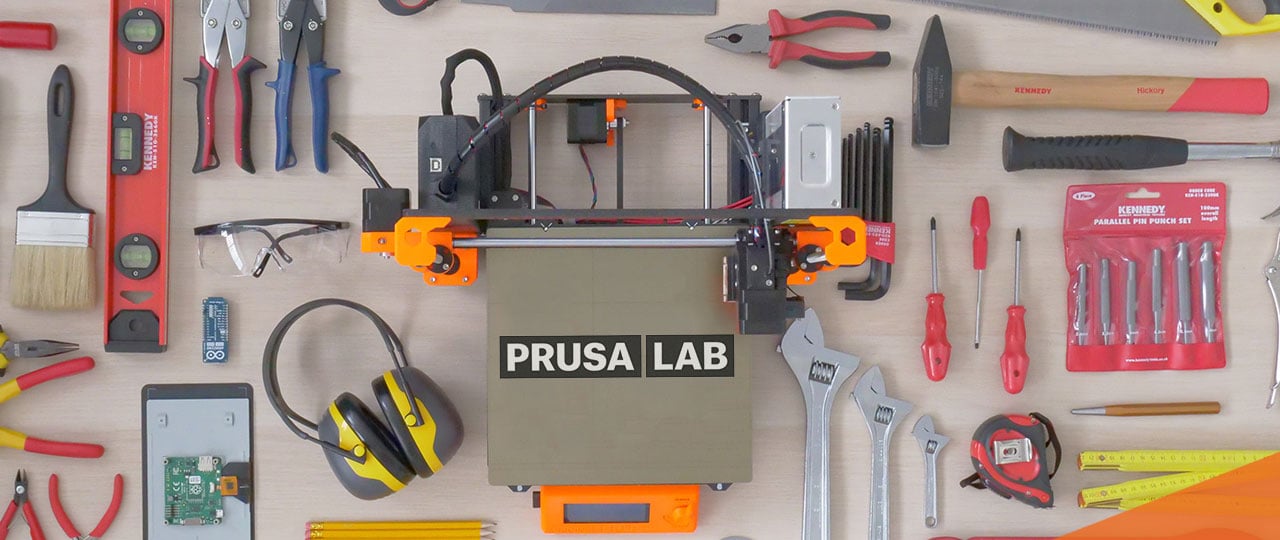

PrusaLab

COMMUNITY MAKERSPACE/HACKERSPACE

Opened in June 2018, PrusaLab is a maker's dream come true. A fully equipped makerspace/hackerspace (creative open space) stretches over an area of 350 m².

3D printers, CNC Vertical Mill Haas VF2SS, CNC Toolroom Lathe Haas TL-1, Narran Laser cutter, saws, drills, pliers, hammers, electro-workshop items... no matter how complex your project is, we've got you covered! Plus, you can take part in various workshops, lectures or listen to industry-related talks.

Prusa Research in Press

Latest articles about Prusa Research

Reviews and Awards

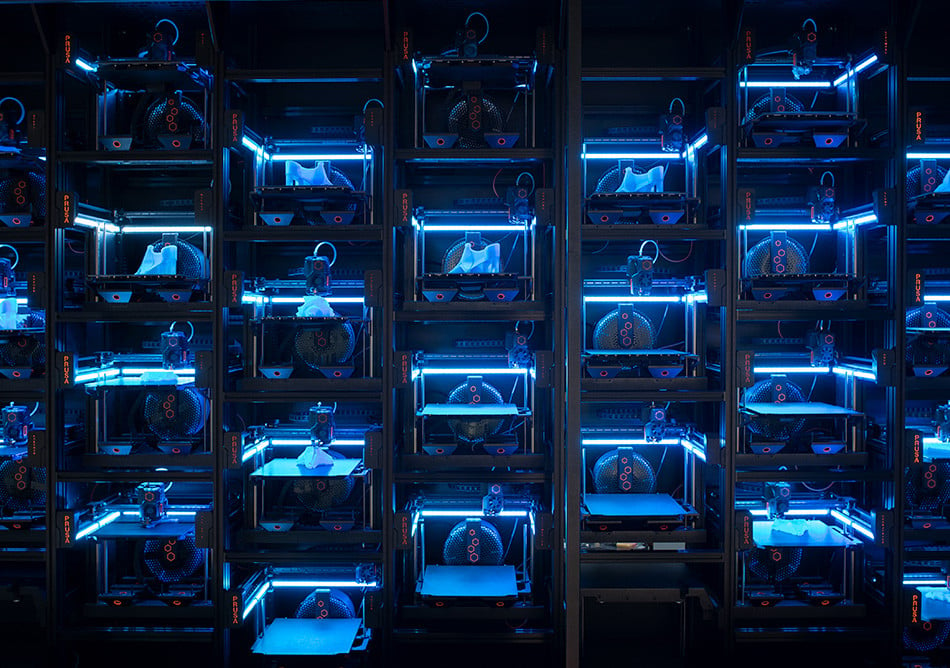

Our print farm

See how hundreds of 3D printers produce parts for new printers!

A 3D printer that can print most of the parts for a whole new printer, that was the idea behind the RepRap project, from which the Prusa i3 was born. But, the more printers you want to print, the more printers you need. Right now, we are running almost 600 3D printers on our farm and, as far as we know, it is the largest 3D printing farm in the world.

We use 2 kg spools to decrease the frequency of filament spool changes. Each printer can print a whole set of plastic parts for MK3S+ in 27 hours. Furthermore, the farm consumes about 6 tons of filament every month.

When you take a look at our huge 3D printing farm you might ask yourself, “Wouldn’t it be better to just use injection molding?” Well, in some cases, it might. Even though a single mold can cost tens of thousands of dollars, it could be more effective. However, using 3D printing gives us one huge advantage – thanks to 24/7 heavy load we can keep innovating and upgrading our printers as we have to resolve every found issue. And in that case, injection molding is no longer a better solution. A 3D printer can also create much more complex parts than injection molding. And our workflow is also way simpler. As soon as we come up with a part improvement, we just test it, upload new gcode to the print farm and within hours we start shipping improved printers to our customers. Basically, we are leveraging one of the biggest advantages of 3D printing to the maximum.

Contact Us

Prusa Research a.s.

EU VAT Number: CZ06649114

Partyzánská 188/7A

17000 Prague 7

Czech Republic