United States

United States🔥 Reduced FedEx Shipping for CORE One! 🚀

Frequently Asked Questions | Latest News | Versions | Community | Prusament for PPE | Contact

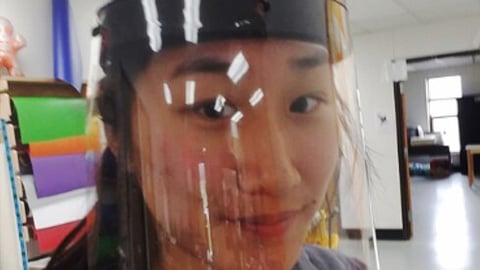

3D printed face shields for medics and professionals

Open-source face shields anyone with a 3D printer can help produce. Join the community-driven effort to help professionals in your area.

In reaction to the acute shortage of protective wear for medical personnel in the current pandemic situation, we have quickly developed and started to mass-produce protective face shields. We have already printed and donated almost 200.000 shields to medics and other professionals in the Czech Republic.

But the shortage is global and veryone with a 3D printer can help! 3D printing communities across the world became a massive driving force in the effort to produce protective wear for those, who need it the most.

This is why the design of the shields is fully open-source, anyone can produce it and/or modify it. Also, the shields are mdea from easily accessible and inexpensive materials. We would like to ask you to help us by spreading the word or even joining the collective endeavor - as a community, we can help thousands of people in need.

Reach out to institutions in your local area and ask them if they could use some additional protective wear (chances are they definitely could!). It’s not only about hospitals and other first responders like police officers and firemen, but also nursing homes, dentists, or just grocery store staff - simply put, you could offer your help to all those who now have to stay in the service or be in contact with many other people in the time of crisis.

The final design called Prusa PRO Face Shield meets the standard of EN 166:2001 for protection against drops and sprays (protection class 3). If you want to manufacture shields in large quantities, you should ask for a certificate in your country. We have prepared the article about the certification process which can help you.

Find & create local communities and start helping!

You can also order Prusa Pro Face Shield on our e-shop

Better safe than sorry

Before you start printing, there are a few things to keep in mind...

1

While assembling the shields, be extremely careful, use a face mask and gloves. In other words: act as if you are infected! Consult the personnel you are making the shields for, they could give you advice regarding additional precautions!

2

Consult in advance the means of collecting and distributing the shields safely - avoid spoiling your hard work by e.g. insufficient protection during transport.

3

Use the design as it is, or improve it however you like. Make sure that the changes and improvemenets are based on a real-life experience of those, who use these shields.

The entire world is helping

When we started supplying local doctors and frontline staff with protective shields, we had no idea how quickly this effort is going spread throughout the entire world. Thank you, everyone, who decided to join the cause!

On March 18th, 2020, we announced the start of protection shields manufacturing and distribution - we barely had the resources to cover the local demand. However, in an incredibly short amount of time, people from all over the world started joining the cause and produced tens of thousands of shields.

The story was covered by worldwide media like Bloomberg, AFP, BBC, Forbes, Hindustan Times, CNET, TechRadar, BoingBoing, Linus Tech Tips and hundreds of local news websites.

If you are still in need of 3D printed protection shields, try contacting one of these wonderful projects!

Don't miss: Check out this great video by Smarter Every Day about "How to Help Your Hospital".

Covidstop.ca

Canada

A coordinated effort to get 3D printed faceshields into the hands of those that need them. Shop3D.ca will cover the cost of filament, shipping and logistics, making it free to volunteer or get protection for front-line workers. You can request free face shields or volunteer your 3D printer.

Operation shields up!

USA

Operation Shileds Up! is based on donations and the work of volunteers. You can request free face shields or join their cause with your own 3D printer.

3D crowd UK

United Kingdom

With over 80.000 face shields in production and more than 3400 volunteers on board, 3D Crowd UK is a massive effort to deliver PPE to frontline staff in the UK. You can request face shields or join as a volunteer with a 3D printer.

Makes vs virus

Germany

Maker vs. Virus is a massive German project that brings together frontline staff and other people in need of protective equipment with makers and makerspaces.

3D Verkstan

Sweden

Due to the shortage of personal protective equipment in Sweden, website 3D Verkstan decided to support the local cause and produce protective shields for doctors and nurses. You can join them with your 3D printer.

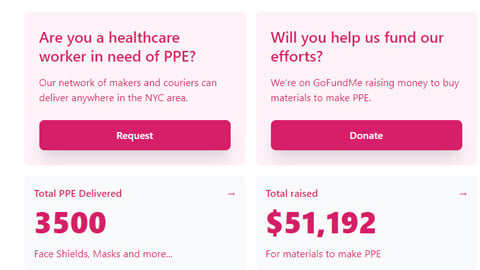

NYCMAKERSPPE

New York

NYC Makes PPE is a group of engineers, makers, and healthcare professionals leveraging DIY manufacturing technology to support PPE production in NYC. You can request protective equipment and help raise funds for the cause.

Covd3d.fr

France

This platform puts professionals in contact with the public and volunteers to organize the creation and distribution of personal protective equipment during the Covid-19 pandemic.

Open works COVID-19

Baltimore

In the face of a critical shortage of protective equipment for front line health workers, Open Works has launched a collaborative project to 3D print face shields. You can donate to the cause or sign up to print at home.

We the builders

Baltimore

We the Builders is partnering with local organizations Open Works and Innovation Works in Baltimore, Maryland USA to coordinate the supply chain, production, and delivery of protective face shields that can be used on the front lines.

Maker works

Ann Arbor, MI

Maker Works not only produce, but also collect and distribute protective equipment delivered by volunteers. You can join their project with a 3D printer and/or donate material such as ABS sheets.

Peterborough PPE Initiative

Canada

An ad-hoc collective of citizens working together to make Personal Protective Equipment (PPE) products for frontline workers, especially in Peterborough area.

Operation PPE

New York

Cornell AAP and Sabin Lab are collaborating with Cornell Engineering, Cornell CIS and many others across the community to 3D print and laser cut visors and protective face shields for doctors, nurses, and healthcare professionals on the front lines at Weill Cornell Medical.

NJ strong with PPE

New Jersey, USA

A group of student volunteers making and donating face shield for the medical professionals in New Jersey in USA - NJPPE.org

They're working 24/7, printing faceshields and donating all of them to local hospitals fighting with COVID19.

Combine LA

LA county, USA

Tens of thousands of EMT’s, emergency room staff and other healthcare workers across LA County are being exposed to asymptomatic COVID-19 carriers every day. Many do not have adequate Personal Protective Equipment (PPE) to keep themselves or their patients safe.

CombineLA is manufacturing PPE to donate to local hospitals and medical facilities.

Northumberland.io producer alliance

Northumberland, Canada

The Northumberland.io Producer Alliance is a self-organized group of local manufacturers, makers, engineers, producers and volunteers. The group is sharing ideas, resources, expertise and production capacity to create a local supply chain for the production and delivery of Personal Protective Equipment (PPE)—principally face shields.

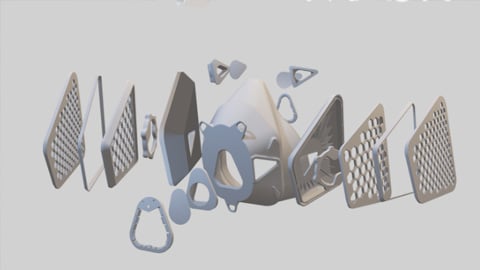

Maker mask

Seattle, WA

The team created and published an open source design for a 3D printed respirator, dubbed the Maker Mask.

The design has been approved by the NIH for all general community applications: This approval applies for use outside of the direct healthcare setting and benefits critical front-line essential service providers. The Maker Mask is also a great option for essential service resources providing our communities with food and other needed supplies.

Prusament PETG orange for PPE

In reaction to the acute shortage of protective wear for medical personnel in the current pandemic situation, we started producing Prusament PETG orange for PPE.

To support everyone who produces 3D-printed PPE, such as face shields, we decided to make Prusament PETG Orange for PPE available with a heavy discount.

This Prusament PETG is primarily made for printing PPE (Personal protective equipment). The material composition matches Prusament PETG Prusa Orange, however, to speed up the production, the diameter tolerance is ±0.03mm and the winding is not as perfect as on the usual Prusaments. It's still a high-quality filament, which we've been using on our print farm for a long time.

Latest news

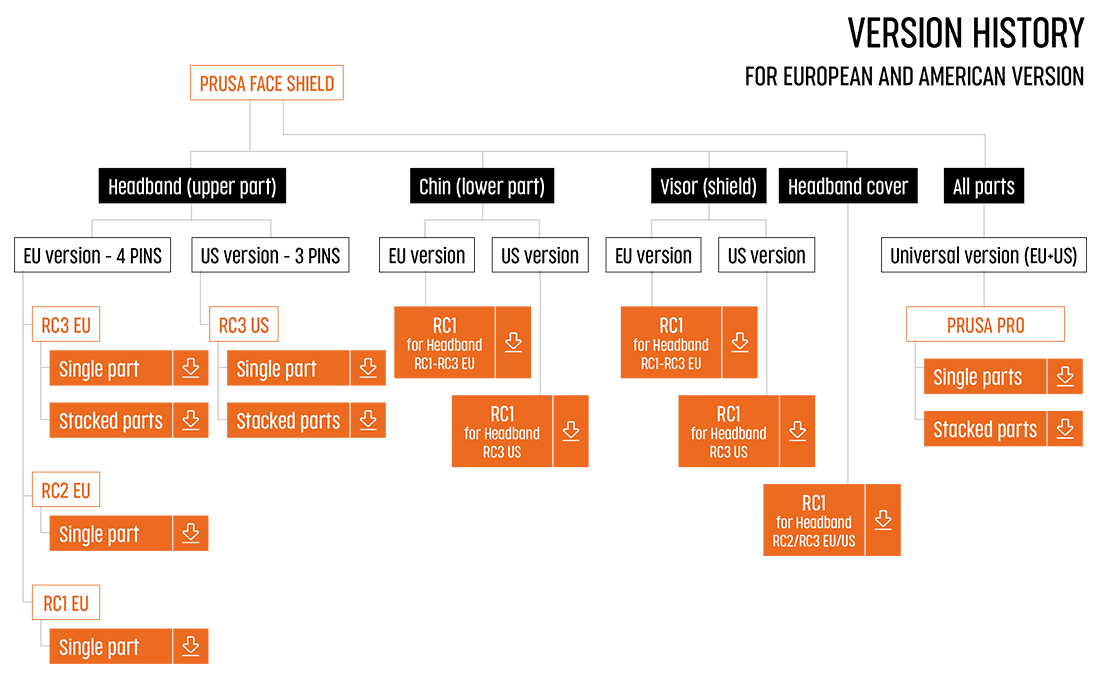

Versions

Do you have a question? Contact us via [email protected].